- Home

- Sword Brands

- Windlass Swords

Windlass Swords

Windlass Swords (Windlass Steelctafts), based in Uttaranchal, India are one of the oldest sword companies still in production. Established in 1943 by Mr VP Windlass the company was originally founded to supply Khurki Knives to the British Army.

Manufactured in: Hand Forged in India

Steels Used: 1065 and 1095 carbon steel

Price Range: US$70 – $395

Official Website: http://windlass.com/

In the late 1970s they began to export their swords to the US and have over time grown to dominate the market for functional medieval and ancient sword replicas. However, true to their roots, they also continue to supply various military organizations throughout the world with their ceremonial swords, and have even made quite an impact in Hollywood – with their swords being selected for use in the movie itself and the officially licensed replicas.

Famous for using good quality steel (from 1065 to 1095 carbon steel, depending on the requirements of the sword) and heat treating it with a specialized state of the art heat treating furnace, the end result is an extremely consistent product. Shipped unsharpened as standard (with a 1mm edge) many places offer a decent sharpening service for an additional fee if required.

Their products are typically priced in the $100 to $300 mark and are exclusively available through their US distributor (owned by Windlass Steelcrafts) Museum Replicas Limited (MRL)

MAIN PRODUCT LINES

MEDIEVAL, VIKING & RENAISSANCE SWORDS

Probably their most popular line, Windlass Steelcrafts makes a huge variety of one handed and two handed medieval swords as well as a reasonable number of Renaissance rapiers and ‘Musketeer’ swords. The general consensus in the sword community is that their short and one handed swords are on the whole nicely done, though their longer swords can sometimes tend to be too thin and ‘whippy’ for any real practical use (though this does vary from model to model).

ANCIENT SWORDS

While Windlass Steelcrafts make a small selection of Ancient Greek and Roman swords – the historical accuracy of these blades tends to be left wanting, though many are quite serviceable and functional – just the attention to detail is often somewhat off. Most of the swords in this line have been around for years and comes across as something of a side project compared to their medieval line. However as the steel is so good, they are worth modifying for those requiring a more historically accurate sword.

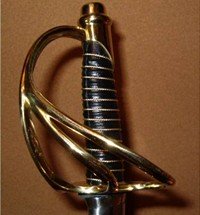

MILITARY SWORDS

Naturally, as they are contracted by the armed forces to produce good quality Military Presentation Swords – Windlass Steelcrafts also make many of these swords available to the public, as well as more historical blades such as American Civil War Swords and other fine Cavalry Swords. Considering the price tag, these blades are exceptionally good value for money and easily the best on the market. As such, they make great authentic gifts for friends and family in the military.

FANTASY SWORDS

Perhaps the second biggest part of their business, Windlass Steelcrafts produce a large variety of officially licensed movie swords – both for the actual industry itself and the fans. Unlike most other movie swords, Windlass movie replicas are considered to be fully functional and made by the exact same processes as their other blades. They have a small selection of fantasy swords – and have dabbled in this area for several side projects, but they tend not to stay in production for very long.

HOW THEY ARE MADE

Forged from high quality, high carbon steel and tempered with the most advanced heat treating processes available they produce a consistent – if mass produced – product.

Both flexible and light weight, these swords are ideal for practicing historical swordplay techniques and on the whole are nicely balanced with a distal taper to properly distribute the swords weight to closely approximate the historical originals.

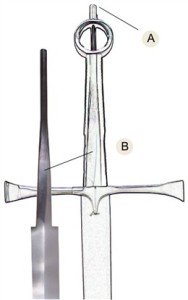

As you can see from the diagram – Windlass swords are (A) of threaded or peened construction with (B) the tang forged as part of the sword.

The end result is a sturdily made sword that can handle shockwaves that travel down the blade into the handle on impact.

While they are not shipped sharp, with a 1mm thick edge they are easily sharpened – though some sellers can save you the effort and have them sharpened up with a beveled edge for a small additional fee.

VIDEO: Making of Windlass Swords

KNOWN ISSUES

Gap in a Windlass Sword

Gap in a Windlass SwordApart from the usual kind of Quality control issues often found on mass produced swords at this price point – Windlass Steelcrafts are most often criticized for two main things – overly whippy blades and poor hilt construction.

The heat treating process that makes their swords so reliably flexible often seems to become problematic on their longer swords. A general rule of thumb is that any blade over 32″ is almost definitely far too whippy to use as it was intended, and practically useless for thrusting.

The second most common issue is that some Windlass swords have a somewhat rattly hilt construction that makes a disconcerting ‘tink-tink’ sound when wielded.

Most of these swords can be identified by the ‘V’ shaped shoulder which tends to leave a small gap between the blade and the hilt. Easily enough fixed by shimming (sticking something into the gap) or an application of polymer epoxy resin, this is actually more annoying than anything else and does not effect the swords overall durability.

WHERE TO BUY

Windlass Steelcrafts swords are available from their retail arm in Atlanta, Museum Replicas Limited HERE (Museum Replicas is owned by Windlass Steelcrafts). There are often various discount coupons on offer if you know where to look for them - and if not, we have a special discount code for a 10% discount on all swords that you can use:

10% OFF COUPON CODE

SBG2023

(you can also get the discount if phoning an order in, 1-800-883-8838)

Otherwise, the best place to pick up Windlass Swords is here at Kult of Athena, where they stock them at very comparable prices.

OFFICIAL SBG REVIEWS

Windlass European Sword

A joy to wield and one of the best value for money medieval swords out there period. $175

Windlass Bastard Sword

Extremely well made and a fantastic bastard sword at a bargain price. $193

Windlass Sticklestad Sword

Awesome handling, solidly made and incredible value for money. $242.95

Windlass Christus Imperat

Our reviewer said: For those having little time and/or who are averse to reading long texts: Go out and buy the thing! $324.95

Windlass Scimitar

Historically accurate, solidly constructed and excellent value. $179

Windlass Ulfberht Sword

Maybe not quite as good as the originals, but quite good for the money. $244.95

Windlass Leuterit Sword

Attractive, good handling, solidly built - even the scabbard is nice..! $238

Battlecry Agincourt Sword

A serviceable and decent sword for the price, though the blackened finish does put some off. $282

Battlecry Culloden Basket-Hilt

The Battlecry version of the Windlass Basket Hilt Sword, great handling, sharpened and overall, good value. $292

Windlass Hero's Warsword

With a blade bigger than the whole length of most two handed swords, this sword is a monster and very affordable too. Loosely based on the historical 'Wallace' Sword. $256

Windlass Classic Medieval

Definitely not a bad sword for the money, and a true Windlass classic. $249.95

Windlass Spartan Lakonian

Almost as tough as the Spartans themselves. A nice effort. $130

Windlass Pompeii Gladius

Actually quite historically accurate, and as tough as nails. $195

Windlass Raptor

Just a solidly made, cool looking and affordable functional fantasy saber. One of Windlass' best swords. $193

Windlass Damascus Viking

A nice piece of functional sword art, though a little tip heavy. $449.95

MRL Create Your Own Sword

Mount it up your way - a decent arming sword with your choice of fittings. $188.95

Windlass 1860 Cavalry Sword

A whole lot of sword for a very reasonable price. One of the best saber deals around. $125.95

Windlass Basket Hilt Sword

In production for nearly 3 decades, a solid time tested replica, though a but too heavy.. $256.49

Windlass 15th C. Longsword

A little to 'whippy' to thrust as well as it should. Average at best and not Windlasses finest, but neither is it their worst. $220

Windlass Roman Pugio

Is it a dagger or a shortsword? Whatever it is, it's not that bad, but not that great either.. $95

Windlass Heron Mark Sword

An authentic replica from the wheels of time series. A good replica, but a pretty average sword. $247

Windlass Pilsen Rapier

So much potential, with great stats and a nice blade. But if you have normal sized hands, its almost unusable out of the box. $220.45

Windlass Falchion

So much potential, but it doesn't quite make the grade. $166.50

I hope this information on Windlass Swords has been helpful. To return to the Sword Manufacturers Dossier from Windlass Swords, click here