Recent Articles

-

Christmas Sword Buying Guide 2025

Dec 03, 25 10:53 PM

The Sword Industry: recent history and future directions..

It is important to understand the sword industry from a bird's eye view. How it has changed over the years, both for good and for bad, is something every sword buyer should know.

Are you buying at a time when quality problems or shipping issues are rife, has quality gone up or down over the years, and what's coming next?

We start with a reprint from our defunct sister site, 'Sword Manufactures Guide'

2005 to 2010: The Golden Age of Swords... OR "These WERE the good old days"...

Original Article By Paul Southren, Dec 2010

Never before have there been so many affordable, decent quality swords available - and never before have they been refined to this degree..

Since 2005 we have seen an EXPLOSION of swords being made to try and suit the needs and requirements of the more discerning members of the sword community, a trend that has indirectly benefited each and every sword buyer.

Even swords designed for mass market consumption such as movie swords have benefited from this refinement - such as swords made by Windlass Steelcrafts that were munitions grade battle ready instead of stainless ornamental..

But for the more discerning sword buyers the changes have been even more dramatic.

In this article I will be taking a look at the industry over the last 5+ years from a 10,000 ft bird's eye view: summarizing the changes, trying to identify the trends and make a few educated guesses about which direction the sword industry is headed into the future...

Medieval Swords - Sharpened Crowbars No More

The Late, Great Rick Williams with a typical sub $300 beater

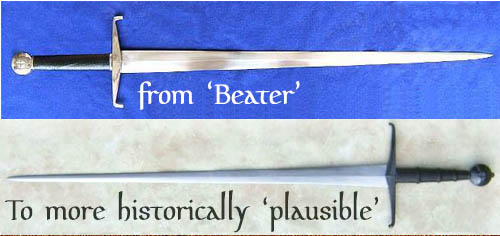

The Late, Great Rick Williams with a typical sub $300 beaterBack in 2005, there were only a handful of choices for 'battle ready' medieval swords. Back then, sub $300 swords were pretty much all 'sword shaped crowbar' clunkers and the only other option were expensive high end historical replicas..

But in the last 5 years, the gap between these two extremes has closed dramatically. It all began with Clyde Hollis from Generation 2, who started working with the guys from the early SBG Sword Forum - soliciting feedback to turn big clunky beaters made in the Philippines into much more refined, historical swords.

It was far from an easy process, with some terrible problems with tempering that had to be overcome early on - but it all changed when the late sword historian Hank Reinhardt came onboard - and now the difference between an early model Gen 2 sword and a current Legacy arms/Gen 2 sword is remarkable...

Recognizing the trend, many other medieval sword makers started to respond in a similar way.

I still recall the first time I saw the medieval knight sword by Darksword Armory, which handled pretty darn well for a beater. And pretty much fell in love with the line when I tested it hard and it withstood everything I threw at it..

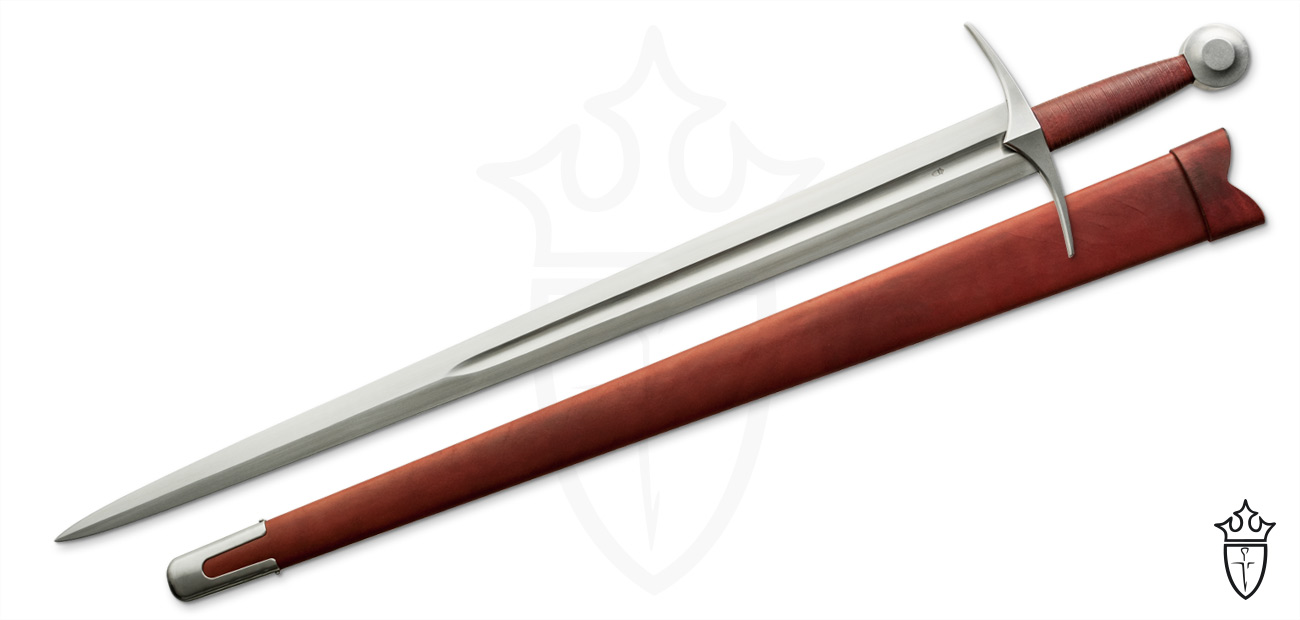

Even though they started from a good position - their swords too began to 'evolve'. From threaded pommels to peened, from extremely heavy blades to much lighter and better balanced blades, then mild steel fittings with cord riser and leather wraps, and from truly deplorable scabbards to scabbards that now look almost like they were custom made - they have, and continue to, take it to the limit! To every criticism they have responded, and many of their swords today are barely recognizable.

Each change made by one sword maker effected the other, and it was during this time that an entrepreneurial and intelligent gentleman by the name of Sonny Suttles took over the helm at Valiant Armory and began to resurrect them from the ashes of obscurity..

Under Sonnys direction, valiant team up with American sword and sword furniture makers Angus Trim, Christian Fletcher and Odinblades John Lundemo to design swords, try out a heap of Chinese forges, work with the BEST quality suppliers there - and out the other end come up with swords like THIS: for around $600 instead of $1,500 or more.

Biggest problem was always demand exceeding supply

Biggest problem was always demand exceeding supplyNot to be left behind, the Hanwei forge - who had previously always struggled a bit with their medieval swords, teamed up with Gus Trims friendly rival, Michael "Tinker" Pearce to create swords design by Michael and made and their forge at Dailan: sub $300 swords designed around Michaels advanced understanding of sword handling dynamics and secondary nodes.

With the gap closing fast between high end and entry level swords, high end makers like Albion and Arms and Armor had to struggle to stay in business, raising their prices several times and trying their best to keep up.. And while times have been hard for them, and the future uncertain, they will always have their die hard fans due to their commitment to quality, customer service and museum based research and development.

Overall, an amazing and dramatic transformation, but one that was certainly not limited to just the medieval sword market..

Japanese Katana

At the start of 2005 the only half decent sword under $300 you could call 'entry level' was Hanwei's Practical Plus Katana and Kris Cutlery - everything else was either stainless steel garbage or extremely (extremely) expensive..

And then along came the infamous 'Chinatana' ('Chinese made Katana') onslaught, starting on eBay but soon spreading like wildfire..

Overinflated prices on stainless steel Katana started to be pushed downwards in price by basic, machine made carbon steel blades made by such as Masahiro, Musashi swords and other unnamed, generic brands..

Quality was (and remains) hit and miss with these mass market makers, but from the free for all of cheaply made blades and mass produced fittings - some solid sellers started to emerge.

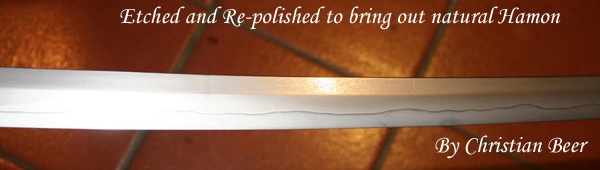

Cheness Cutlery were one of the first, starting with hand forged blades in average fittings and experimenting with new steels such as 9260 Spring Steel blades that people either loved or loved to hate (personally, I still find a Tenchi to be a solid investment, and have a Kaze Katana that I had custom mounted in a dragonfly silk ito that is one of my favorite swords in my collection).

What the Future Holds (Sword Darwinism)

Now I'm no prophet, but I've been involved with the sword industry long enough to be able to see which sort of direction it's taking..

On the one hand, with people having less money to spend on their hobbies and collections, they want to get as much information as possible before they buy because they can't afford to make a mistake. They also want and demand proper old fashioned customer service - and in the best traditions of natural selection, the crappy sellers and products are being exposed, weeded out and are dying off..

At the same time, the sword community of 2010 is more educated than ever before, and the market continues to respond to their feedback and demand. This 'push-pull' dynamic is having a powerful effect on all levels of the sword industry..

Medieval sword enthusiasts have come of age, the old 'clunkers' are just not acceptable anymore - and even though the divide between lovers of beaters and historically accurate swords still exists, it is continually evolving towards a happy medium of medieval swords that are both robust and handle as much like the historical originals as possible.

Historical plausibility, if not accuracy, is now an essential ingredient as never before.

Japanese sword enthusiasts are demanding greater attention to detail, and to a large degree they are getting it! Swords like the SBG Kuramono and Ronin Katana's Dojo Pro line pay attention to even the smallest details in a way that, until recently, was only ever seen on swords above the $1000 price point..

And even the low-priced machine made swords are being refined to create basic collector grade swords such as the $80 'Bamboo' Katana by Musashi Swords (man, it almost seems that if you call a low-end sword 'bamboo' it is going to be lucky!).

But the search for low cost, highly functional swords and beaters is also taking a new direction - and a third option is emerging (one I'm personally quite interested in to be honest) and that's the low cost, tactical style blades such as the Hanwei tactical Wakizashi and the $23 Cold steel two-handed machete katana (love the concept of this thing, shown in the video below).

But the question must be asked, how much further can the sword industry 'push the envelope'? After all, there are cost limitations as to how much time can be spent making a sword that will sell for at or around $300 - especially with China, who produce the overwhelming majority of functional swords on the market these days, becoming less competitive due to the rising costs of wages and their currency floated against the US dollar..

Maybe the machine made blades like the Bamboo are the future? Or maybe the great strides forward made over the last 5 years push towards the upper limits of what the relatively small size of the sword market can sustain (it must be remembered that the sword market, especially for the kind of swords serious enthusiasts want and love, is a tiny niche)..

Maybe the future from here is all about tweaking and refining the revolutionary steps that have been taken up to now.

Cheap swords sold to the mass market will still dominate on volume - but perhaps incremental refinements and greater accessibility of KNOWLEDGE available to those who care to know what to look for, along with more responsible and informative marketing of swords by sellers is what the future holds?

Whichever way it goes, the truth of it is that today we are in a GOOD place, spoiled for choice as it were! While there is still a lot of junk out there, it's easier than ever before to find a solid, functional sword at a decent price - so much so that it's no so much a case of sorting the jewels from the junk, but on choosing the right jewel!

BUT, and this is an important qualifier - there will probably ALWAYS be minor issues on lower end swords. They have got a LOT better in the last 5 years (and the flaws, less dangerous) - but NOTHING will ever really replace the ability to tweak a production sword to take care of any small, non critical annoyances and some good old fashioned KNOWLEDGE on what to look for when you get a new sword, as well as what is normal and what is not (especially because, who KNOWS what really happened to your sword when it was in transit!)...

While the amount of messing about to turn a sub US$300 sword into something you could trust your life with on a medieval battlefield has been dramatically reduced and almost entirely eliminated in some ways, it will ALWAYS pay to know the difference between a minor cosmetic thing you can fix in a jiffy, and a serious fatal flaw..!

Conclusion

'"These are the good old days" - and it would seem, they may be getting even better - or at least more refined..

It's almost as if a tsunami of swords crashed onto the shores of the market and now that the tide is withdrawing, we find lying buried in the sand some seriously amazing treasures that continue to refine and evolve before our eyes!

The divide between high end and entry level swords is starting to blur as more swords of high quality that were far out of the reach the average sword buyer start to come into range. And who knows, within the next 5 years we may see the cheapest functional swords made from modern materials with as few 'moving parts' as possible, and more traditional swords continue to refine themselves until a $300 sword is more like todays $1,000 one.. (and the $1,000 swords become like todays $2,500 blades).

In short, it's all looking pretty darned good!

Yes, it's not all clear sailing though.. There are threats to sword ownership worldwide - as there will always be the irresponsible idiot in the mix who makes things harder for OVERWHELMING majority of true sword enthusiasts.. But even bans like those in the UK, while hardly to be encouraged, force manufacturers to make 'traditional' swords for collectors, and in a strange way act as a further filtering mechanism that bolsters the push towards further refinements.

Whichever way it goes, NOW is most definitely a golden age that shows signs of continual refinement and improvement - and in my own small way, I'll be doing my best to try and keep it all on track for this community that shares my sword passion and infatuation.. ^_^

Paul Southren

10 YEARS LATER...

It is now late 2020, and so I can look back with hindsight to see how far off my predictions for the sword industry were..

I was right that the market for medieval beaters had passed and the new emphasis was on historical accuracy and handling. Oakeshott typology became more important than ever, and the buzzword of the decade was 'distal taper' and 'spring tempering' with nothing less being acceptable.

Albion made a come back in a big way, and there was a shift that as Game of Thrones became increasingly popular, so did medieval swords, with Katana almost neck and neck for the first time..

Unfortunately during this time, much of the hard work we did to show the industry behind the scenes backfired.

eBay marketers started setting up mini-workshops or buying seconds and defective lots and openly lied bout, well, pretty much everything to the point that by late 2020 - the majoriy of the forges we visited just 7 years earlier are closed or are motballed (see my article eBay Scams Exposed: the article China based eBayers don't want you to see..)

I was right abot a move towards tactical style blades with few moving parts - this is what the entire A.P.O.C. series is based upon.

Flex Testing the 9260 Spring Steel Blades

Flex Testing the 9260 Spring Steel BladesCustomers are fussier than ever and make it hard to keep prices low when a sword is returned for minor stuff that the previous generation of collectors would have just fixed up themselves or accepted as normal. By these standards, they would be upset with the finish of a Gus Trim sword, regardless of how well it cuts and handles.

Or this one, one of our own Forge Direct Swords..

It was the only one ever rejected - because while everything was very tight, the seppa was not dead straight on one side, and so it was sold for pennies on the dollar in a scratch and dent sale..

Prices have not gone up despite HUGE pressures to do so, at the most 10% in the last 10 years. Some prices have even gone down!

My vision of swords with interchangeable parts was partly realized on a small scale with 3D printing from the Printed Armory and on a larger scale with Rawlings training swords, but is not looking likely anytime in the foreseeable future.

New companies like Kingston Arms and Dragon King shook things up, Kingston Arms working with Gus Trim like Valiant did - even selling some of his own swords through their brand and designing the rest.

But it was Ronin Katana that surprised everyone with their medieval sword line - now to the point that they are recognized by many HEMA groups and sword critics around the world as some of the best value for money medieval sword sttles out there - partially because they sell them at prices well below what the sword industry normally would (Add another 50% or more and you are close to what they SHOULD be sellling for).

What I did not see coming was how bad the challenges to the industry would become..

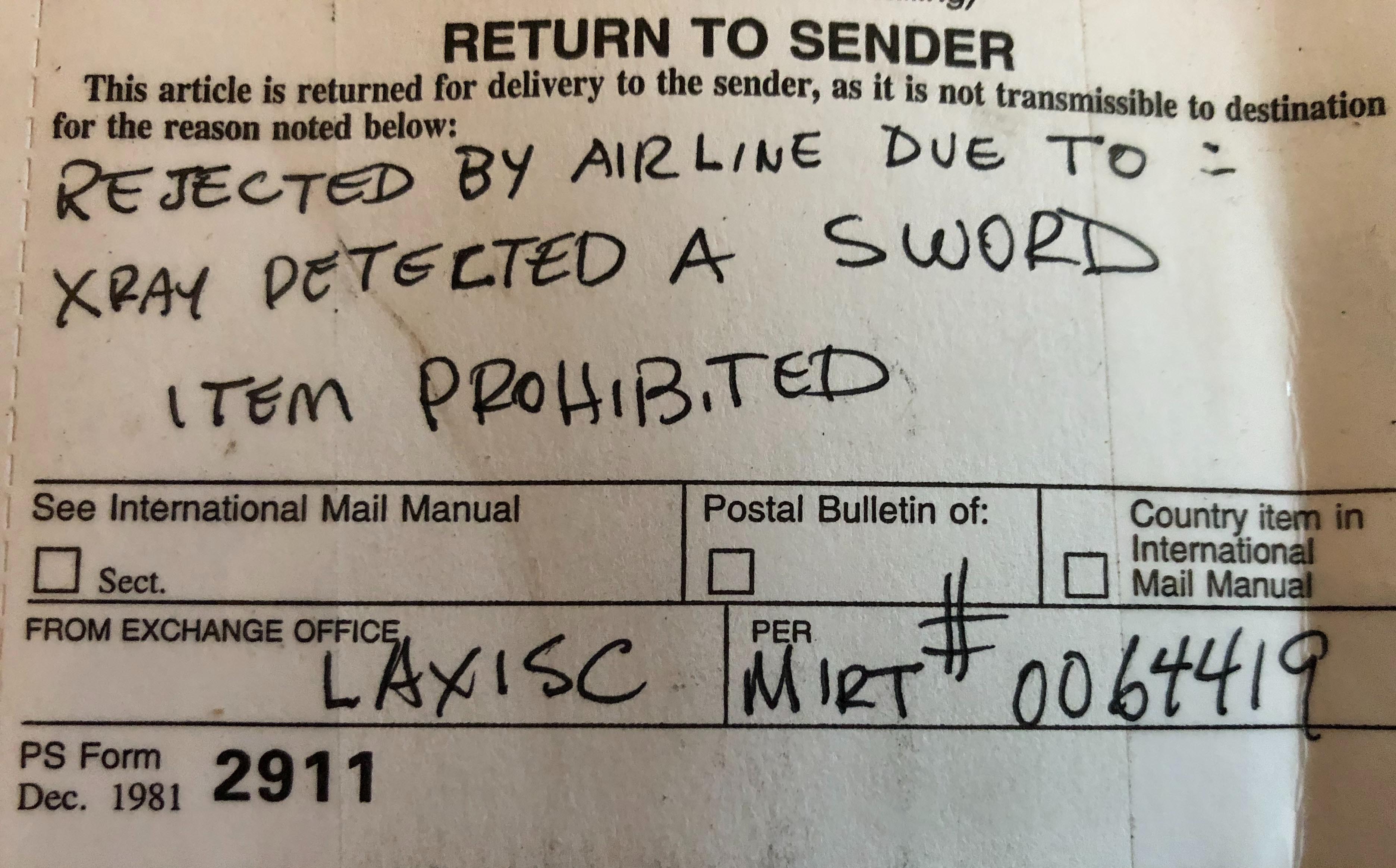

The Mysterious No Fly Sword Directive

We had seen the UK sword ban, and the restrictions in Victoria, South Australia. But in 2018 shipments going from the USA were suddenly being rejected or confiscated all over the world, just at Christmas time of all times..

But in 2019 it got worse, and by the end of 2019 International shipping had all but disappeared..

There was no global manifest, no-one to petition, and no-one to challenge. Just suddenly, shipments all over the world were coming back with tags like:

The other carriers all started to become hit and miss, and the US suddenly found itself able to ship by road to Canada only. The rest of the world had ben cut off from the sword industry - and to this day there are few solutions other than parcel forwarding services (of which we list the most sword friendly here)

Another Guess at the future

Of course, the world entered a new era in 2020 with the outbreak of the SARS-COV2 Pandemic - and the after effects of a prolonged global shutdown are yet to be known, but will no doubt have a serious impact on the industry.

But assuming we move past this, I see an influx of more cheap and nasty blades and copies than ever before, but I also see new alliances and opportunities for SBG and its friends.

Custom made swords are the way of the future. And what was once sub $300 will now end up as two classes - sub $200 'rubbish' and $500 mid grade dominating. The old stand by of $300 being your best entry level sword price are most definitely on the way out..

So we will end up with ultra cheap functional bladed swords, $500 ranged 'new entry level' and then probably custom swords. Lots of custom swords and limited edition runs - and likely - a move away from China as being the main producer of swords, with more eventually being made using more CNC and 3D printing tech.

Maybe then they will prdouce my own 'dream sword' the 'true ultimate'. And no, it is not a light saber. But it would change the sword industry like never before..

What is sharper than a shard of broken glass or obsidian?

And did you kmow one of apples contractors are working on 'flexible glass'..

Razor sharp, unbreakable...?

Now THAT would revolutionize the Sword Industry once and for all..

I hope you enoyed this article on the sword industry. To return to the Sword Manufacturers Dossier from the Sword Industry Recent History and Future Directions, click here

Buying Swords Online Can Be DANGEROUS!

Find the Best Swords in the:

Popular & Recommended ARTICLES

The ONLY true free online magazine for sword enthusiasts. Delivered once a month on the 1st day of the month, no filler and no BS, just the latest sword news & info delivered straight to your inbox.